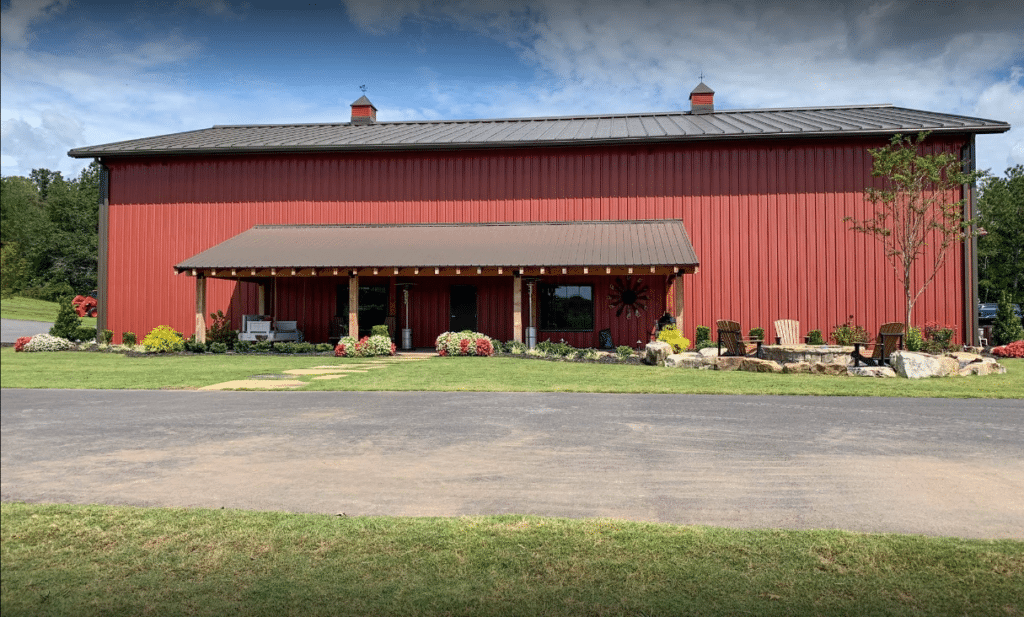

Steel Garage and Workshop Usage

Homeowners

A metal garage building, pre-engineered from commercial-grade steel, gives plenty of space to shelter a car, truck, boat, or lawn maintenance equipment such as a riding lawnmower, from the elements.

Because prefabricated metal garage buildings are customizable, they can be crafted to any size so that there is plenty of room for multiple vehicles, with a doorway system wide enough and tall enough to accept the largest of vehicles.

In addition to steel garage buildings, homeowners can erect steel workshop buildings. Attempting to do woodworking or enjoy a man cave in an already crowded garage can be difficult. The solution is stand-alone metal workshop buildings. As with a garage, metal workshop buildings can be built to any specification, and the interior is easily customizable as a workshop, a man cave or a she shed (or lady lair!).