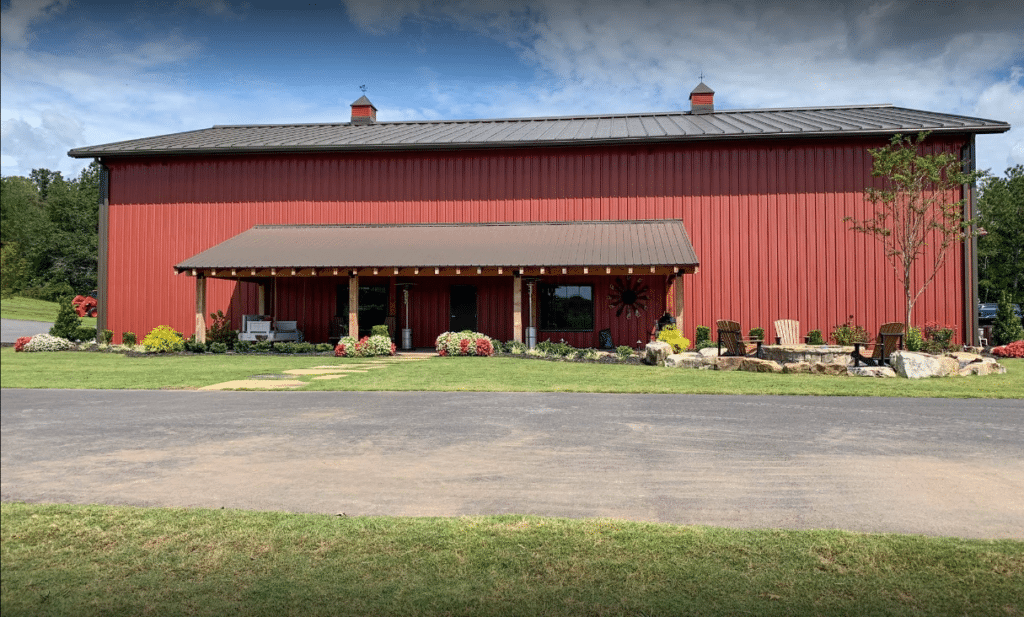

Steel Industrial Building Usage

Pre‑engineered steel is the go‑to choice for today’s light‑ and mid‑duty industrial facilities, spanning:

-

Manufacturing & fabrication bays – CNC shops • metal/wood workshops • modular‑home or panelized‑wall lines

-

Process & packaging plants – food‑grade rooms • bottling & canning halls • plastics or composites molding

-

Fleet maintenance & equipment service – truck, bus or heavy‑equipment repair shops with bridge‑crane capacity

-

Distribution & cross‑dock hubs – high‑bay inventory, pick‑and‑pack mezzanines, temperature‑controlled staging

-

Waste‑transfer & recycling centers – clear‑span tipping floors, baler/compactor lines, covered material storage

Steel’s clear‑span frames, quick erection and fire‑/corrosion‑resistance have pushed it to more than 95 % of new industrial construction, a share that keeps growing as owners demand faster build times, flexible interiors and low life‑cycle costs.