Brewing beer is not just an art but also a science. To ensure the highest quality and consistency of your brews, it is crucial to start with a solid foundation—a well-planned brewery construction and layout.

The number of operating craft breweries reached an all-time high of 9,761 in 2023, including 2,092 microbreweries, 3,502 brewpubs, 3,910 taproom breweries, and 257 regional craft breweries.

In this article, we will explore expert tips for brewery construction, covering everything from understanding the basics to choosing the right materials, implementing safety measures, and considering cost implications.

Whether you are a seasoned brewer or just starting, these insights will help you embark on a successful brewery construction journey.

Table of Contents:

- Understanding the Basics of Brewery Construction

- Planning Your Brewery Layout

- Choosing the Right Materials for Brewery Construction

- Safety Measures in Brewery Construction

- Cost Considerations in Brewery Construction

- Conclusion

- Frequently Asked Questions

Understanding the Basics of Brewery Construction

Before diving into the specifics, it is important to grasp the fundamentals of brewery construction. A key aspect to consider is the location of your brewery.

Building a brewery involves a meticulous process that goes beyond just constructing a physical space. It requires a deep understanding of the brewing industry, including trends, regulations, and consumer preferences.

By immersing yourself in the world of brewing, you can make informed decisions that will shape the success of your brewery.

Importance of Location in Brewery Construction

The location of your brewery plays a vital role in its success. Factors such as accessibility, proximity to suppliers, and zoning regulations should be taken into account. Additionally, consider the availability of natural resources needed for brewing, such as water quality and temperature.

Furthermore, evaluate the potential market and target audience in the area to ensure the viability of your brewery.

Choosing the right location for your brewery is not just about finding a place with enough square footage. It’s about strategically positioning your brewery in a way that maximizes visibility and accessibility to your target market.

Consider factors like foot traffic, nearby attractions, and the overall vibe of the neighborhood to create a unique and inviting brewery experience for your customers.

Pro tip:

Breweries are usually categorized under Commercial or Industrial zoning. These classifications permit business and industrial activities, such as manufacturing and the sale of goods and services. Breweries are often allowed as a primary use in these zones, but special permits or conditions may apply. It’s essential to seek advice from the local zoning department or a land use attorney to understand the specific zoning requirements for a brewery in your area.

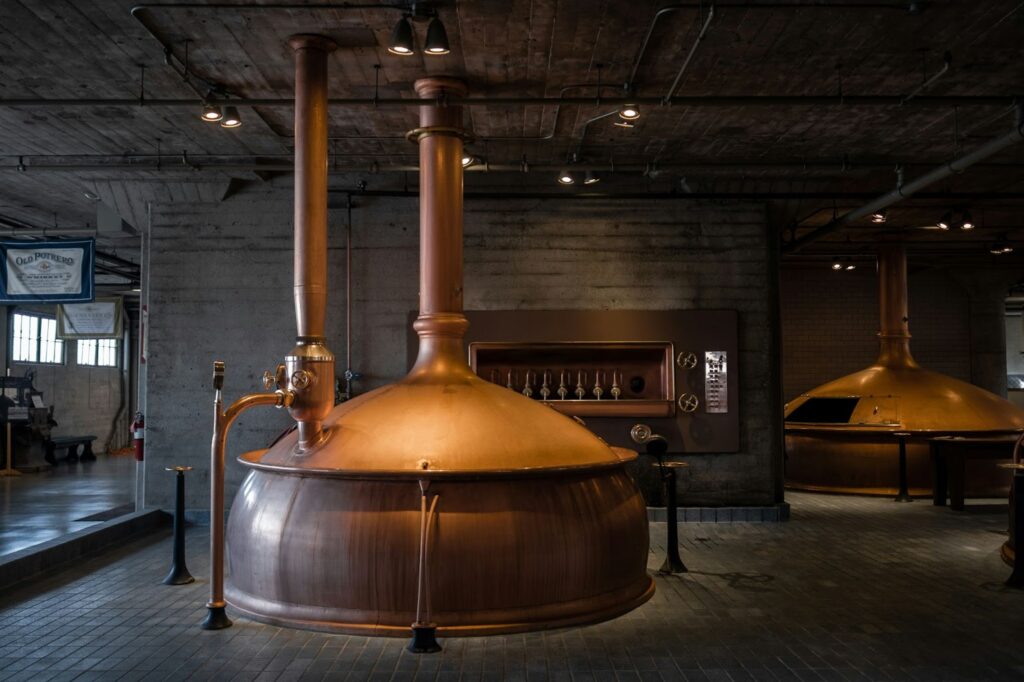

Necessary Equipment for a Brewery

Equipping your brewery with the right tools is essential for efficient brewing processes. Some of the vital equipment includes mash tuns, fermentation tanks, brew kettles, cooling systems, and storage vessels. It is crucial to choose equipment that suits your brewing capacity and style, while also considering future expansion possibilities.

Investing in high-quality equipment is a cornerstone of a successful brewery operation. By carefully selecting equipment that is durable, efficient, and tailored to your specific brewing needs, you can streamline your production process and maintain consistency in the quality of your beers.

Additionally, staying updated on the latest brewing technology and equipment innovations can give your brewery a competitive edge in the market.

Planning Your Brewery Layout

Once you have a solid understanding of the basics, it is time to dive into the planning phase of your brewery construction. A well-thought-out layout will optimize space utilization and streamline workflow.

When planning your brewery layout, it’s essential to consider not only the functional aspects but also the aesthetic appeal of the space.

Incorporating elements of design that reflect your brand identity can create a unique and inviting atmosphere for both employees and visitors. From the choice of materials to the color scheme, every detail plays a role in shaping the overall ambiance of your brewery.

Space Utilization Tips

Efficiently utilizing the available space is crucial in a brewery. Consider factors such as maximizing floor space, vertical storage, and creating designated areas for specific brewing processes. Implementing a smart flow pattern will minimize downtime and enhance overall productivity.

Another important aspect to consider when optimizing space utilization is future scalability. Designing a layout that allows for easy expansion or modification as your brewery grows can save you time and resources in the long run.

Planning for potential equipment upgrades or increased production capacity ensures that your brewery can adapt to changing demands without major disruptions.

Did You Know?

Vermont has the highest concentration of breweries in the U.S. As of 2023, Vermont had 14.7 breweries per 100,000 adults over 21, the highest number of craft breweries per capita. Maine and Montana follow closely behind, with 14.2 and 12.3 breweries per capita, respectively.

Workflow Considerations in Brewery Design

Designing a brewery layout that optimizes workflow is crucial for smooth operations. Consider the sequence of brewing steps and ensure a logical flow from raw material handling to fermentation and packaging.

Create designated areas for each process, minimizing cross-contamination risks and improving efficiency.

In addition to physical layout considerations, incorporating technology into your brewery design can further enhance workflow efficiency. Automated systems for ingredient handling, temperature control, and quality assurance can streamline processes and reduce human error.

Integrating data analytics tools can provide valuable insights into production performance, helping you make informed decisions to optimize your brewery’s operations.

Choosing the Right Materials for Brewery Construction

The choice of materials for brewery construction is paramount in ensuring a durable and functional brewery. Consider the pros and cons of various construction materials before making a decision.

Building a brewery involves more than just putting up walls and installing equipment. It requires careful consideration of the materials used to ensure the longevity and efficiency of the operation.

Each material has its own set of characteristics that can impact the brewing process and overall functionality of the brewery.

Pros and Cons of Various Construction Materials

Stainless steel is a commonly used material due to its durability, hygiene, and resistance to corrosion. However, it can be expensive. Other options include concrete, which provides excellent insulation properties but may require special coatings to prevent chemical reactions, and wood, which adds a unique aesthetic but may require more maintenance.

Another material to consider is glass, which is nonreactive and provides a visually appealing look to the brewery.

However, it is fragile and may not be suitable for all aspects of brewery construction. Each material choice should be evaluated based on its specific benefits and drawbacks to ensure the brewery meets your needs.

Durability and Maintenance Considerations

When selecting materials, it is important to consider their durability and maintenance requirements. Regular inspections and maintenance routines should be implemented to ensure the longevity of your brewery.

Additionally, invest in materials that are resistant to chemicals and temperature fluctuations, as these are common challenges faced in brewing environments.

Furthermore, consider the environmental impact of the materials chosen for your brewery construction. Opting for sustainable and eco-friendly materials can not only reduce your brewery’s carbon footprint but also appeal to environmentally conscious consumers.

Balancing durability, functionality, and sustainability is key to creating a successful brewery that can withstand the test of time.

Safety Measures in Brewery Construction

Brewery construction should prioritize the safety of workers, equipment, and the brewing process. Implementing proper safety measures will minimize risks and ensure a secure working environment.

When considering safety in brewery construction, it is essential to also focus on structural integrity. Ensuring that the building materials used are fire-resistant and meet safety standards is crucial.

Additionally, incorporating proper ventilation systems to prevent the buildup of hazardous fumes is vital for maintaining a safe working environment.

Fire Safety in Breweries

Fire hazards are a concern in breweries due to the presence of flammable materials and equipment. Install adequate fire suppression systems, such as sprinklers and fire extinguishers.

Develop emergency response plans, conduct regular drills, and ensure all staff members are trained in fire safety protocols.

Moreover, it is essential to have designated fire exits that are easily accessible and marked. Regularly inspecting and maintaining electrical systems to prevent short circuits and potential fire hazards is also crucial in ensuring the overall fire safety of the brewery.

Ensuring Worker Safety During Brewery Operations

Worker safety is of utmost importance in any brewery. Provide proper training on using equipment, handling chemicals, and following safety protocols.

Implement safety devices, such as guardrails and nonslip flooring, to prevent accidents. Regularly inspect and maintain equipment to ensure it is in safe working condition.

Furthermore, promoting a culture of safety awareness among workers through regular safety meetings and encouraging reporting of any potential hazards can significantly enhance the overall safety of brewery operations.

Investing in personal protective equipment (PPE) for all staff members and enforcing its use can provide an additional layer of protection for workers during their daily tasks.

Cost Considerations in Brewery Construction

While building a brewery, it is crucial to consider the financial implications and create a realistic budget.

Budgeting for Your Brewery Construction

Develop a comprehensive budget that includes all expenses, from construction materials and equipment to permits and licenses. Research costs for each element and consult with professionals to gain accurate estimations.

Include a contingency amount to account for unforeseen expenses that may arise during the construction process.

When creating your budget, it’s essential to factor in the costs of specialized brewery equipment such as fermenters, kegs, cooling systems, and bottling lines.

These items can represent a significant portion of your expenses but are crucial for the brewing process. Additionally, consider the costs of hiring skilled labor for the installation and setup of this equipment to ensure it functions properly.

Hidden Costs in Brewery Construction

Be aware of hidden costs that may not be immediately apparent. These can include architectural and engineering fees, site preparation, utility connections, and compliance with building codes and regulations.

Careful planning and thorough research will help you identify and account for these costs upfront.

Another often overlooked cost is the expenses associated with branding and marketing your brewery.

Building a strong brand presence through logo design, packaging, and advertising is essential for attracting customers and standing out in a competitive market. Allocating funds for marketing initiatives early on can help establish your brewery’s identity and reach a wider audience.

Conclusion

Constructing a brewery requires careful consideration of various factors, from location and equipment selection to layout planning, materials, safety measures, and cost considerations. By incorporating these expert tips into your brewery construction process, you can lay a solid foundation for producing exceptional brews.

SteelCo has over 23 years of experience dropshipping pre-engineered metal building (PEMB) materials nationwide and offers commercial construction services in Georgia and Tennessee for a wide range of building and client industry types.

On the PEMB side, we assist our clients in navigating local building codes and construction timelines, providing basic conceptual designs and stamped engineering plans to simplify the process of obtaining necessary permits and licenses.

Learn more about our expertise in PEMB commercial buildings and how we can assist you in your brewery construction project.

—————————–

Frequently Asked Questions

What is the difference between a brewpub and a microbrewery?

A brewpub combines a craft brewery with a pub culture, serving fresh beer on-site alongside food. A microbrewery is any facility that produces fewer than 15,000 barrels of beer annually, with 75% or more of its beer served off-site.

How much does it cost to start a microbrewery?

Starting a microbrewery typically involves an initial investment ranging from $300,000 to $350,000. This includes costs for brewing equipment, facility renovation or rent, ingredients, branding, legal fees, staffing, and operational expenses.

What is a contracting brewery?

A contracting brewery is a business arrangement in which a brewer who does not have their own brewing facilities partners with an existing brewery to produce, package, and sell their beer. This allows the contract brewer to focus on recipe development and marketing without the overhead of owning and operating a full-scale brewery.

Is building a brewery a good idea?

The brewing industry can be profitable, with the average profit margin for craft breweries at approximately 14.7%, which is generally higher than restaurants or bars. Aiming for a profit margin of about 25% or more is typical for breweries. However, it’s important to consider factors such as production costs, location, and the business model.

Is steel a good option for brewery construction?

A clear span layout is highly recommended for breweries because it eliminates interior support columns, providing an open and flexible space. Steel clear span buildings are an excellent choice as they offer wide open interior spaces without any separation. Clear span designs enhance safety, allow for quick and efficient processing, and provide ample room for brewing equipment and storage. Additionally, metal buildings, including steel clear-span structures, have high resistance to fire, which is essential in a brewery where flammable materials are present during production.

—————————-

Check out these related articles:

> Industrial Building Construction: A Deep Dive

> Construction Services For Your Building Needs

> Navigating Construction Permits For Steel Buildings – Requirements And Things To Know