In metal building construction, ensuring the durability of the structure is paramount. One important aspect that plays a significant role in metal building construction is the roof pitch. For those unfamiliar with the concept, roof pitch refers to the steepness or slope of the roof, and there are is also a minimum pitch for metal roofs.

Metal roofing has been gaining popularity among U.S. homeowners, with its market share increasing from 12 percent in 2019 to 17 percent in 2021. This trend is driven by the roofing’s durability, energy efficiency, and sustainability, particularly in areas susceptible to extreme weather events.

It is a crucial factor in determining the overall performance and longevity of a metal building.

Table of Contents:

- Understanding the Importance of Roof Pitch in Metal Buildings

- Steps to Optimize Metal Building Roof Pitch

- The Impact of Weather Conditions on Roof Pitch

- Minimum Pitch for Metal Roof

- Maintenance Tips for Optimized Roof Pitch

- Future Trends in Metal Building Roof Pitch

- Conclusion

- Frequently Asked Questions

Understanding the Importance of Roof Pitch in Metal Buildings

The role of roof pitch in the durability of metal buildings cannot be overstated. A well-designed roof pitch helps to efficiently shed water, snow, and debris, preventing stagnant accumulation that could lead to roof leaks or structural damage.

Moreover, it enhances the building’s resistance to harsh weather conditions by reducing the chances of water infiltration and improving its ability to withstand high winds.

Roof pitch is not only crucial for functional purposes but also plays a significant role in the aesthetic appeal of a metal building. The pitch of a roof can impact the overall look and style of the structure, influencing its architectural design.

Different roof pitches can create varying visual effects, from a modern and sleek appearance with a low pitch to a more traditional and imposing look with a steeper pitch. Architects and designers often consider the roof pitch as an integral part of the building’s visual identity.

The Role of Roof Pitch in Durability

The primary function of roof pitch is to channel water away from the building. By having a steeper slope, drainage is facilitated, preventing the pooling of water on the roof’s surface.

Accumulated water can cause corrosion and damage to the metal panels, leading to leaks and compromising the building’s integrity. A proper roof pitch ensures effective runoff, reducing the risk of water-related issues.

Key Factors Influencing Roof Pitch Selection

When determining the optimal roof pitch for a metal building, several factors come into play. One important consideration is the geographical location and climate. Areas with heavy snowfall or intense rainfall may require steeper pitches to ensure efficient water drainage.

Moreover, wind patterns and local building codes should be taken into account to ensure the roof’s ability to withstand strong winds and meet regulatory requirements.

Another crucial factor influencing roof pitch selection is the intended use of the metal building. Buildings used for industrial purposes may have different pitch requirements compared to agricultural or residential structures.

The function of the building, such as the need for internal clearance or ventilation, can impact the ideal roof pitch.

Additionally, future expansion plans or the installation of solar panels may also influence the decision-making process when determining the most suitable roof pitch for a metal building.

Did You Know?

In the United States, the most common roof pitch for large industrial and commercial metal buildings is 1:12, which means the roof is nearly flat. However, for standing seam metal roofs, there’s typically a minimum pitch requirement of 3:12, which translates to at least 1/4 inch of vertical rise for every foot of horizontal distance

Steps to Optimize Metal Building Roof Pitch

To optimize the roof pitch of a metal building, several steps need to be followed.

By carefully assessing the building’s specific needs, choosing the right materials, and implementing proper installation techniques, the roof’s durability can be greatly enhanced.

Assessing Your Building’s Specific Needs

Before determining the optimal roof pitch, it is crucial to evaluate the specific requirements of the metal building. Factors such as the size and purpose of the structure, local weather conditions, and future usage plans should be taken into consideration. Consulting with an experienced professional can provide valuable insights and expertise to guide the decision-making process.

For example, if the metal building is intended to be used as a storage facility for agricultural equipment, the roof pitch should be designed to shed snow efficiently during the winter months.

On the other hand, if the building is a commercial warehouse located in an area prone to heavy rainfall, a steeper roof pitch may be necessary to prevent water pooling and potential leaks.

Choosing the Right Materials for Your Roof

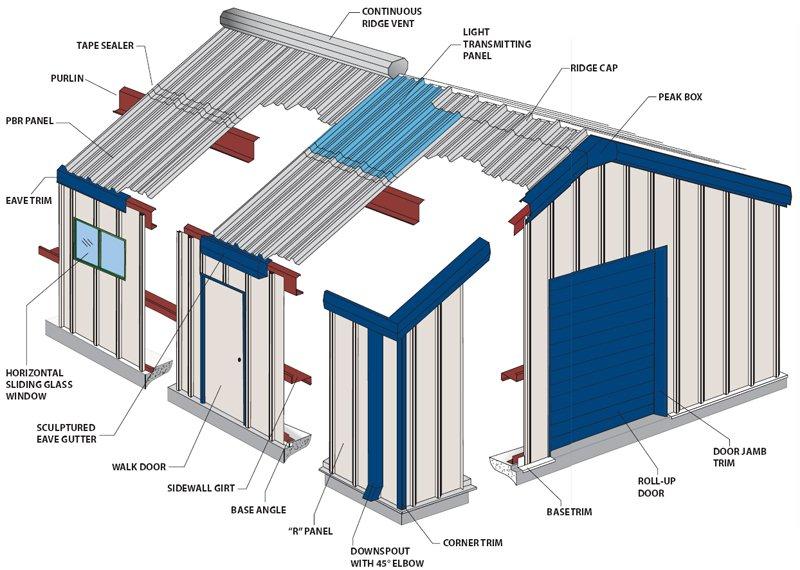

The selection of appropriate materials is essential for optimizing roof pitch durability. Metal roof panels come in different gauges, profiles, and coatings, each offering varying degrees of strength and resistance to corrosion.

Engaging with reputable suppliers and considering specific environmental conditions will help ensure the longevity and performance of the roofing system.

When choosing metal roof panels, it is important to consider factors such as the expected lifespan of the building, the level of maintenance required, and the desired aesthetic appeal.

For instance, if the metal building is located in a coastal area with high salt exposure, opting for panels with a corrosion-resistant coating can significantly extend the roof’s lifespan and reduce maintenance costs over time.

Implementing Proper Installation Techniques

Proper installation techniques are crucial for maximizing the roof’s durability. This includes ensuring secure fastening of the roof panels, correctly applying sealants and flashings, and following the manufacturer’s instructions. Engaging professional installers with hands-on experience in metal building construction can help guarantee the use of best practices for long-lasting performance and protection against the elements.

During the installation process, attention to detail is paramount. Properly aligning and overlapping the roof panels, using the recommended fasteners and sealants, and conducting thorough quality checks can prevent potential issues such as leaks, wind uplift, and premature deterioration.

Additionally, regular inspections and maintenance should be scheduled to identify and address any signs of wear or damage, ensuring the roof’s continued performance and longevity.

The Impact of Weather Conditions on Roof Pitch

Weather conditions play a significant role in determining the optimal roof pitch for metal buildings.

Understanding how different weather elements affect the structure and adopting suitable measures can contribute to its long-term durability.

When it comes to the impact of weather conditions on roof pitch, there are several key factors to consider beyond just snow load, rainfall, and wind resistance.

For instance, in areas prone to extreme heat or intense sunlight, the angle of the roof can also play a crucial role in energy efficiency.

By adjusting the pitch to provide better shading or ventilation, building owners can reduce cooling costs and improve overall comfort within the structure.

Dealing with Snow Load and Rainfall

Regions prone to heavy snowfall or intense rainfall require careful consideration of roof pitch to ensure effective water drainage. Steeper pitches can prevent excessive snow accumulation that might otherwise cause significant stress to the building.

Likewise, proper runoff of rainwater is essential to avoid water-related damage. Implementing adequate insulation and conducting regular maintenance will further safeguard the building against the challenges posed by these weather conditions.

The choice of roofing materials can also impact how weather conditions interact with the roof pitch. Certain materials may be more prone to damage from snow or rain, necessitating a steeper pitch for better protection. Considering the overall climate of the region and the specific characteristics of the building can help in selecting the most suitable roofing material to complement the chosen roof pitch.

Wind Resistance and Roof Pitch

Strong winds pose a considerable threat to metal buildings, and an optimized roof pitch can enhance their resistance. Steeper slopes exert less pressure on the structure, reducing the risk of wind uplift and potential damage.

Understanding local wind patterns and considering the recommendations of wind load calculations can guide the selection of an appropriate roof pitch that ensures the building’s stability and resilience against high winds.

In addition to wind resistance, the aesthetic appeal of a building can also be influenced by the roof pitch. Different pitches can create varying visual effects, impacting the overall architectural style and character of the structure.

By carefully balancing functional requirements with design considerations, architects and building owners can achieve a harmonious blend of form and function in the roof pitch selection.

In metal roofing systems, the concept of roof pitch is critical for ensuring the structure’s overall water shedding capability, thereby enhancing its durability and longevity. The minimum roof pitch for a metal roof is centrally important to consider in the planning and installation phases, as it directly influences the roof’s ability to efficiently manage rainfall and snow.

Minimum Pitch for Metal Roofs

For metal roofs, the minimum pitch often depends on the specific type of roofing system and material being used. Generally, the most common minimum pitch for metal roofing is 3/12. This pitch is steep enough to ensure that water and accumulated snow can efficiently run off, minimizing the risk of water intrusion and the potential damage it can cause.

Importance of Adhering to Minimum Pitch Standards

Water Drainage: A roof pitch below the recommended minimum can lead to water pooling on the roof surface. Over time, standing water can cause corrosion, especially in metal roofs, and may infiltrate the structure, causing leaks and water damage.

Warranty and Insurance: Manufacturers typically specify a minimum roof pitch for their roofing products. Installing a metal roof with a pitch below this recommendation can void the warranty. Similarly, insurance companies might have specific requirements regarding roof pitch for coverage to be valid.

Aesthetic Appeal: Beyond functionality, the roof pitch contributes to the aesthetic appeal and architectural integrity of the building. A roof pitch that is too shallow for a metal roof may not align well with certain architectural styles, affecting the overall appearance.

Snow and Ice Accumulation: In colder climates, a roof pitch that is too shallow may not efficiently shed snow and ice. This can lead to increased weight on the roof structure, posing a risk of damage or collapse.

Special Considerations

- Standing Seam vs. Metal Shingles: Standing seam metal roofs, known for their long, vertical panels, might have different minimum pitch requirements than metal shingles or tiles. Always consult the manufacturer’s guidelines.

- Underlayment and Waterproofing: In cases where a lower pitch is unavoidable, special attention must be paid to underlayment and additional waterproofing measures to mitigate the risks of leaks and water damage.

- Local Building Codes: Always check local building codes and regulations, as they may have specific requirements regarding roof pitch in your area, superseding general recommendations.

While the general rule of thumb is a minimum of 3/12 pitch for metal roofs, understanding the nuances associated with different materials, roof styles, and local regulations is crucial.

Maintenance Tips for Optimized Roof Pitch

Even with an optimized roof pitch, regular maintenance is crucial to ensure the continued durability and performance of the metal building’s roof. Simple yet effective measures can be implemented to identify and address potential issues before they escalate into larger problems.

When it comes to maintaining an optimized roof pitch, one must also consider the importance of proper ventilation. Adequate ventilation plays a key role in preventing moisture buildup, which can lead to mold growth and structural damage. By ensuring that the roof and attic space are well-ventilated, you can prolong the life of your roof and maintain a healthy indoor environment.

Regular Inspections for Long-Term Durability

Scheduled inspections are vital for detecting early signs of damage or wear and tear. This includes checking for loose or damaged roof panels, examining the condition of sealants and flashings, and inspecting gutters and drains for any blockages.

Detecting and addressing minor issues promptly can prevent them from developing into more significant problems, extending the lifespan of the roof.

In addition to visual inspections, it is recommended to conduct regular roof performance evaluations. These evaluations can involve assessing the roof’s ability to shed water, withstand wind loads, and maintain thermal efficiency.

By monitoring the performance of the roof over time, you can proactively address any issues that may impact its long-term durability.

Addressing Common Roof Pitch Problems

Certain problems can arise with roof pitch over time, and immediate action should be taken to rectify them. Issues like ponding water, leaks, or snow and debris accumulation should be promptly addressed to maintain the roof’s effectiveness and prevent any potential damage to the overall structure.

Engaging professional roofing contractors experienced in metal buildings can help identify and resolve these problems efficiently and effectively.

Furthermore, it is essential to consider the impact of environmental factors on roof pitch maintenance. Exposure to harsh weather conditions, such as heavy rainfall or extreme temperatures, can accelerate wear and deterioration.

Implementing preventive measures, such as applying weather-resistant coatings or installing protective barriers, can help mitigate the effects of environmental stressors and preserve the integrity of the roof pitch over time.

Future Trends in Metal Building Roof Pitch

As technology and innovation continue to advance, new trends are emerging in metal building roof pitch design. These trends aim to improve the durability, sustainability, and performance of metal roofs.

Innovations in Roof Pitch Design

Advancements in roof pitch design focus on optimizing the performance of metal roofs. Innovative slope calculations and advanced materials are being utilized to enhance water runoff, increase wind resistance, and improve energy efficiency.

These innovations aim to provide metal building owners with more robust and environmentally friendly roofing solutions.

Sustainability and Roof Pitch Optimization

In line with the growing importance of sustainability, roof pitch optimization is incorporating eco-friendly practices.

The integration of green roofing systems and the use of recyclable or energy-efficient materials contribute to both environmental sustainability and long-term durability, ensuring that metal buildings remain strong and resilient well into the future.

Optimizing the roof pitch of a metal building is vital for ensuring its durability. Understanding the role of roof pitch in water drainage, wind resistance, and overall structural integrity is crucial.

By following a systematic approach to assessing specific needs, selecting the right materials, and employing proper installation techniques, the roof can be optimized for durability.

Pro tip:

Green roofs can reduce building energy use by 0.7% compared to conventional roofs, leading to an annual savings of $0.23 per square foot of the roof’s surface. Additionally, a typical 2-3 story building with a green roof could experience 15-25% savings in summertime energy costs.

Conclusion

Considering the impact of weather conditions and implementing regular maintenance will further enhance the roof’s longevity.

Looking ahead, trends in roof pitch design and sustainability will continue to shape the future of metal building construction. They’ll offer more durable and environmentally conscious solutions.

Since 2001, SteelCo has been dropshipping customizable building materials for pre-engineered metal buildings and steel roofing needs nationwide.

We’re also a locally awarded commercial general contractor in Georgia, managing projects of 200,000+ square feet in various sectors, including industrial, retail/mixed-use, manufacturing and distribution, self-storage, and commercial.

Our general contracting expertise allows us to take projects from concept to reality, customizing them to reflect your industry-specific needs and preferences. Learn more about our services.

——————————–

Frequently Asked Questions

What’s the recommended pitch for a metal roof?

Screw-down metal roofs require a minimum roof pitch of 1:12, whereas standing seam metal roof systems can be as shallow as 0.25:12. Going below this can lead to issues like leaks, pooling water, and premature deterioration.

How long can metal roofing last?

Metal roofing can last up to 75 years when installing a standing seam metal roof. Other types of metal roofs, like screw-down panel roofs, age faster and last only 20-30 years.

What’s the cost of a metal building roof?

The cost of a metal roof varies based on factors like design, style, accessibility, labor, and material type. In the USA, asphalt shingles typically cost between $4.25 and $30 per square foot. If you choose other materials like metal, the range is much smaller typically $8.50 to $16 per square foot.